The Hub Of Operational Know How

Know-How Employees Need

Everything from highly structured industry guidelines (ex. OSHA) to digital work instructions to employee tribal knowledge delivered as bite-sized and easily understandable. Harness expertise across the organization with subject matter experts sharing “How To’s” in short posts or even videos on how they complete their tasks.

When They Need It

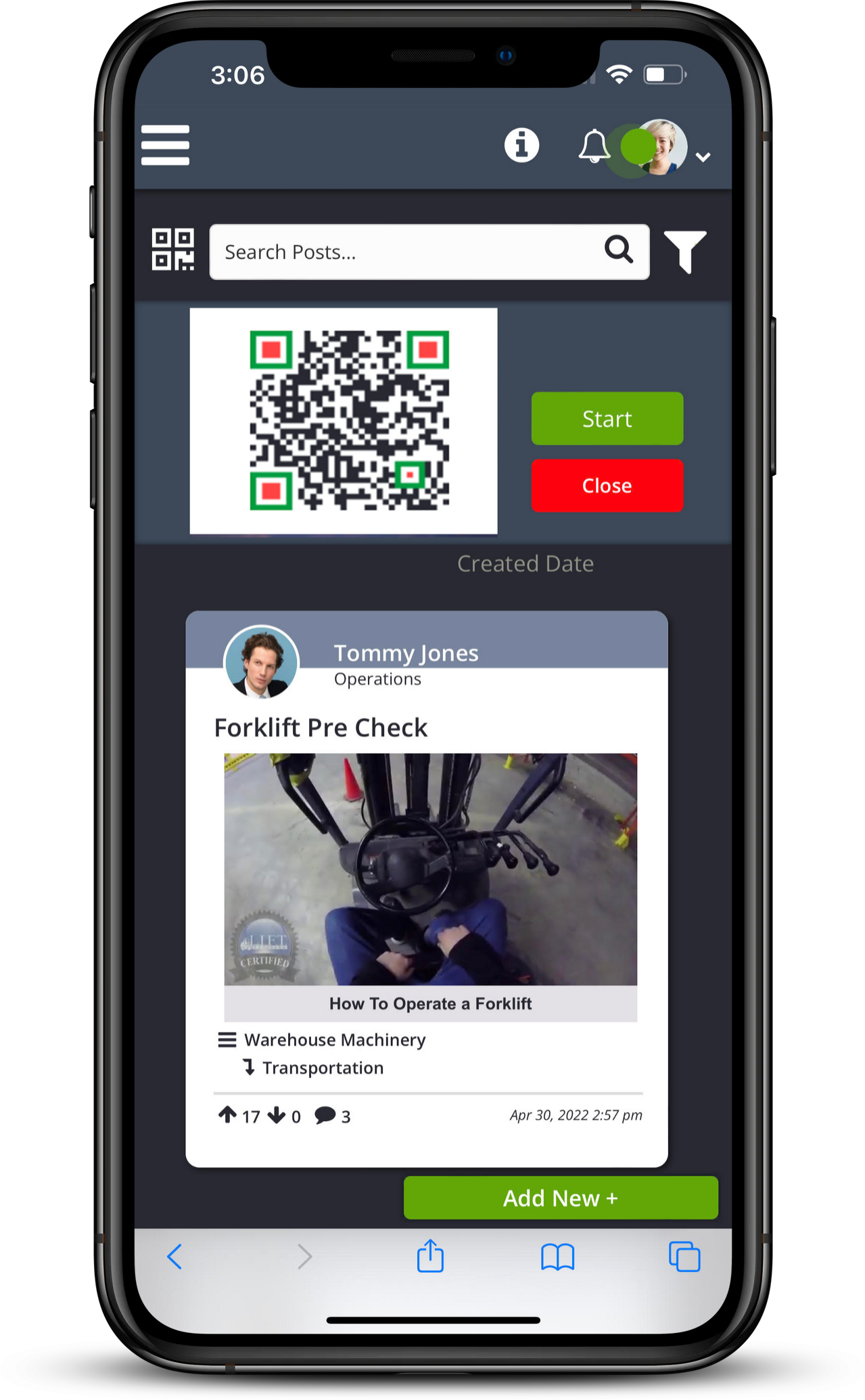

Simply scan a QR code to access knowledge. Frontline workers can easily share their own knowledge, ask questions, and collaborate. The mobile friendly site is designed for distributed teams thereby facilitating collaboration and knowledge sharing across teams separated by location/time/shift/etc.

Connecting the Separated

Create an agile team regardless of geography or timing. The sharing of knowledge between distributed workers can prevent the repetition of errors and promote the adoption of successful strategies by disseminating valuable lessons from one team quickly to others. In addition, digital work instructions facilitate real-time updates, which allows organizations to address emerging risks and safety concerns promptly. The Omega Notes system helps employees share information about challenges and hazards immediately, so that all teams are aware and can take the appropriate action. By sharing information and preventing accidents, breakdowns, and other disruptions, operational risks can be minimized, and overall safety can be enhanced.

Reduce Equipment

Downtime

With Omega Notes, businesses can benefit from faster and more precise equipment repairs and maintenance. Step-by-step guidance and visual aids reduce the likelihood of errors and ensure technicians follow the correct procedures. If equipment does break, simply scan a QR code on the equipment to get on-the-spot troubleshooting. As a result, equipment downtime is significantly reduced, leading to increases in productivity and efficiency.

Continuous Improvement

Iterative updates made in response to the feedback from workers and supervisors leads to enhanced safety and efficiency. The insights generated by users, and data analytics, can be used to identify bottlenecks, determine potential safety hazards, and modify instructions accordingly. As a result of this iterative process, work instructions remain up-to-date along with technology advancements, industry best practices, and emerging safety standards.

Only 10% of job knowledge comes from formal training. 90% is learned by collaborating and doing. With Omega Notes, new employees have access to the organization’s tribal knowledge wherever and whenever they need it. With just a QR code, they can access instructions, videos, and know-how specific to their work environment. Furthermore, the collaborative approach of the platform enables new hires to get quick answers to their questions, troubleshoot issues, or clarify doubts without waiting for a supervisor or mentor to become available. This bite-sized approach to learning in context, as well as timely support, boosts confidence and accelerates the learning process.

Avoid Rework

Implement standardized procedures with clear visuals and multimedia elements that provide step-by-step instructions. Procedures can be updated in real time and immediately disseminated to all relevant personnel in order to minimize issues caused by outdated methods. As a result, employees can verify that each step has been executed correctly by checking their work instructions and/or asking questions to subject matter experts leading to fewer instances of rework and fewer errors.

Unlike traditional approaches, Omega Notes was designed to engage and enable. With the mobile friendly site, employees can get the knowledge they need by simply scanning a QR code on equipment or risk points within an organization. The collaborative, social media like environment promotes knowledge sharing and best practices by enabling employees to share videos, ask questions, and connect with experts all within their workflow.